KL Engineering, Inc.

KL Engineering, Inc.Request A Quote

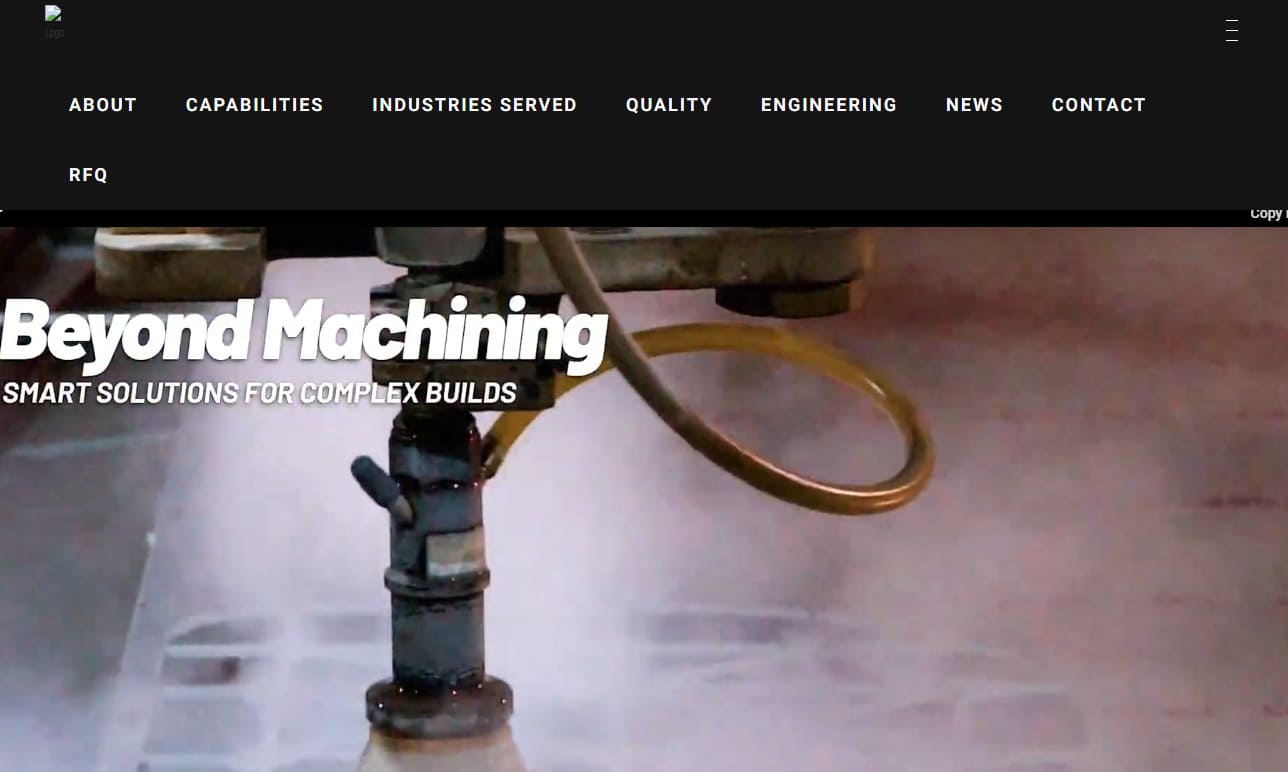

Morgan Hill, CA | 408-966-6940At KL Engineering, Inc., we dedicate ourselves to delivering precision manufacturing solutions that help our customers bring complex ideas to life with accuracy and efficiency. Our core strength lies in water jet cutting, a process that allows us to cut a wide variety of materials with remarkable precision while maintaining the integrity of the raw material. By using high-pressure streams of water, often combined with abrasives, we are able to create clean, intricate cuts without generating heat or causing distortion. This capability makes our services ideal for industries that demand exact tolerances and flawless finishes. We take pride in our ability to work with metals, plastics, composites, stone, and other challenging materials that require careful handling. Our water jet cutting process allows us to cut both thin and thick materials with equal precision, making it a versatile solution for applications ranging from custom prototypes to high-volume production runs. Because the process is cold cutting, there is no heat-affected zone, which ensures that even the most delicate materials retain their properties during fabrication. At KL Engineering, Inc., we view technology as a tool to enhance what matters most: quality, reliability, and customer trust. By leveraging water jet cutting along with our broader engineering capabilities, we continue to push the boundaries of what is possible in precision manufacturing. Our mission is to help our clients succeed by providing them with products and services that are not only accurate and durable but also delivered with the responsiveness and attention to detail they expect from a trusted partner.

Broaching

Broaching CNC Machining

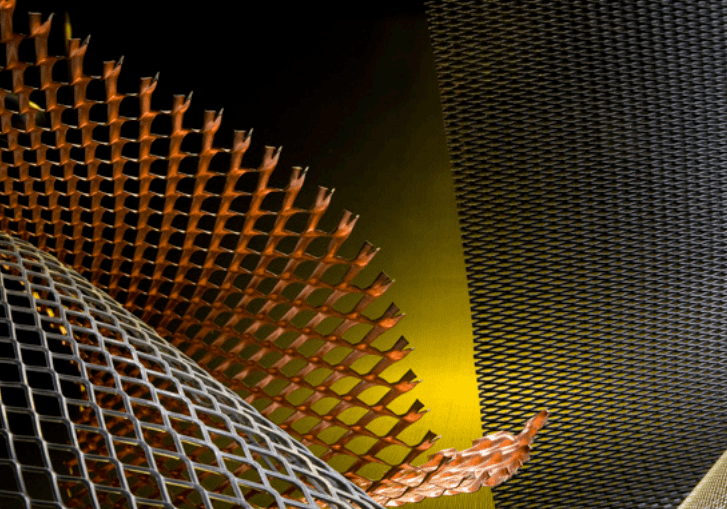

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

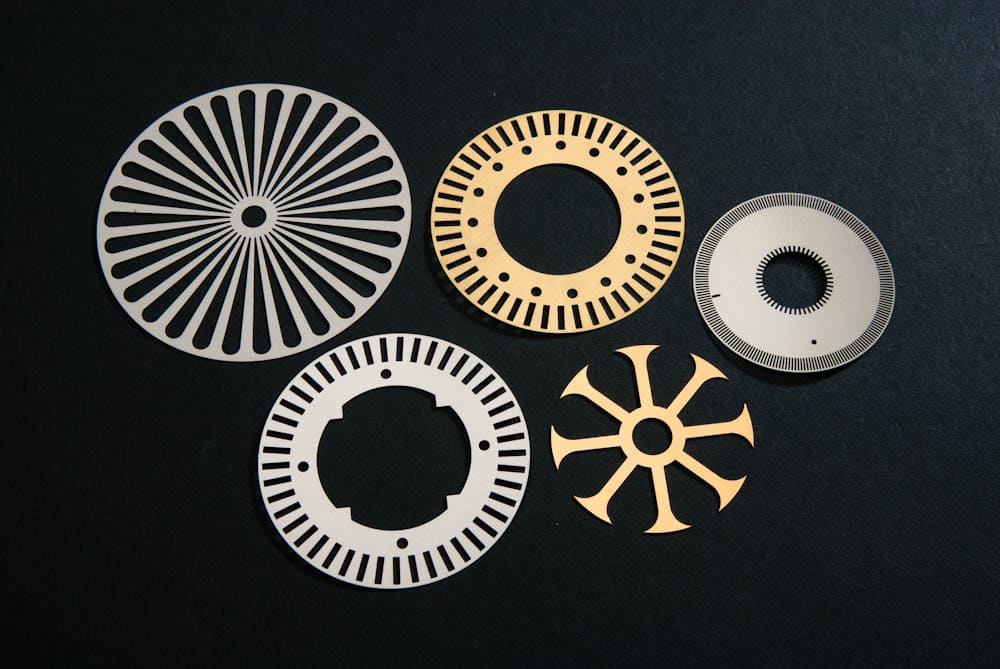

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

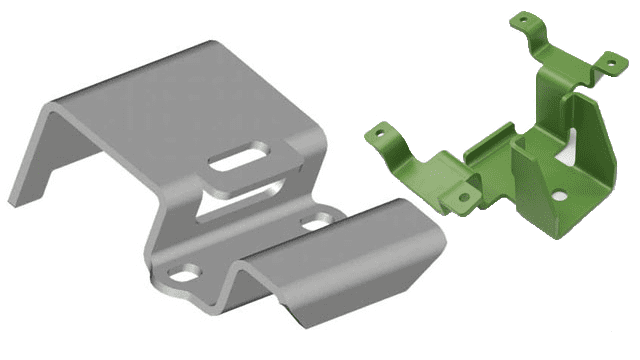

Metal Fabrication Perforated Metals

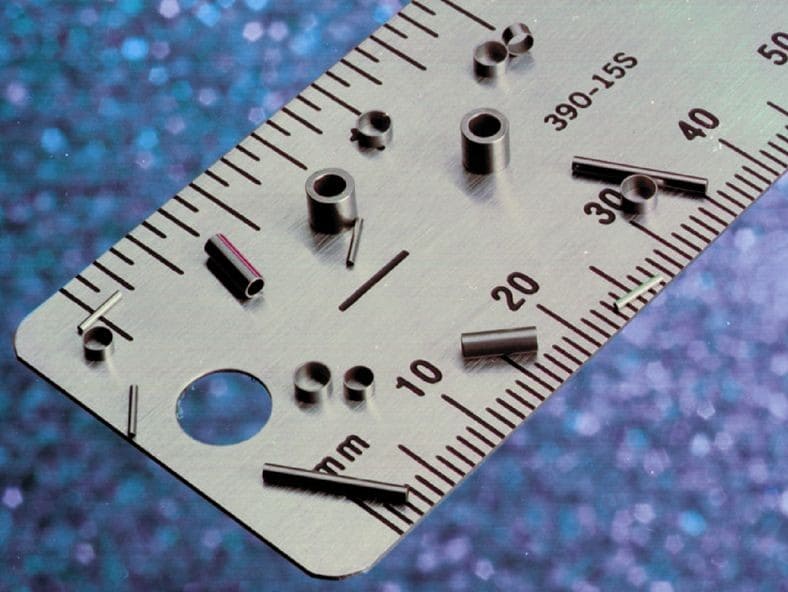

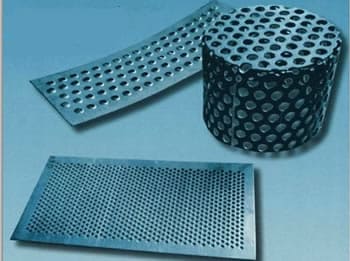

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

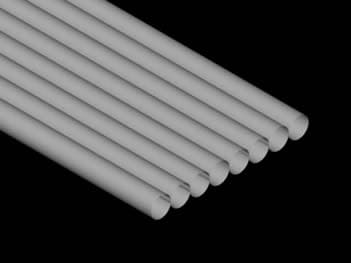

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services