Water jet machining is also known as water jet cutting. Water jet machining is frequently employed in various industrial applications. Softer materials like plastic, rubber, and wood can be sliced with WJM. However, an abrasive material is combined with water to cut tougher objects, such as metals or granite. Abrasive water jet machining (AWJM) is the machining technique in which an abrasive material is employed in water and applied by a very high-pressure jet of water to the workpiece to achieve the desired shape and size, or to remove materials off the surface of a workpiece. Read More…

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

At M.A.R.'s Engineering Company, Inc., we specialize in providing top-notch waterjet cutting services, catering to a multitude of industries. Our team of experts, armed with cutting-edge technology, can precisely cut a variety of materials, including metals, plastics, glass, ceramics, and more. No job is too big or too small for us; we've got the expertise and equipment to handle it all.

At Fruehauf Manufacturing, we take pride in delivering precision-engineered solutions through our expertise in water jet cutting. Our advanced capabilities allow us to cut a wide range of materials with exceptional accuracy, meeting the demands of industries that require intricate designs and high-quality finishes. By utilizing state-of-the-art water jet cutting technology, we offer a...

Barton International is a leading manufacturer and provider of abrasive blasting and waterjet cutting services. With more than 142 years of operation and five generations of the Barton family's leadership, we have cemented ourselves as one of the most trustworthy names in the industry. Today, we have forty stocking locations across North America and have expanded our product offering to more than ...

More Water Jet Machining Companies

Comprehensive Guide to Water Jet Machining (WJM) and Waterjet Cutting Technology

Water jet machining, often referred to as waterjet cutting, is a highly advanced and versatile manufacturing process that utilizes a high-pressure stream of water, sometimes mixed with abrasive substances, to cut or shape a wide range of materials. Thanks to its unique cold cutting process, waterjet machining delivers exceptional precision without introducing heat-affected zones (HAZ) or altering the material structure. Whether you’re researching industrial cutting methods, evaluating CNC waterjet applications, or comparing the benefits of waterjet cutting versus laser cutting, this guide will provide in-depth answers and insights into water jet technology.

Working Theory of Water Jet Machining

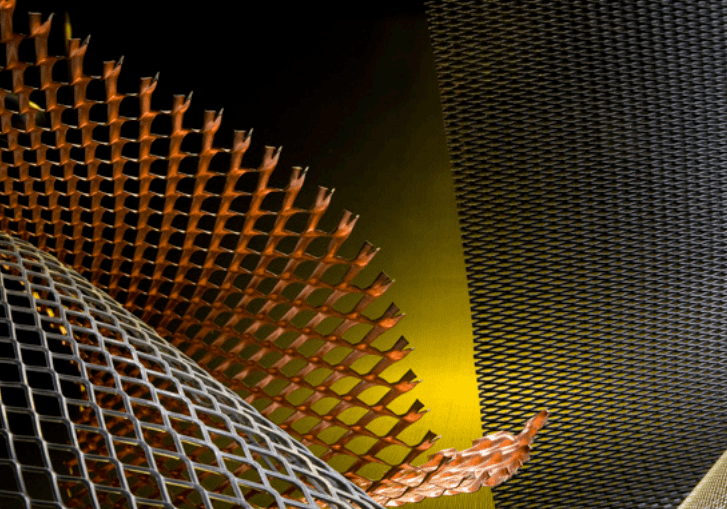

The foundation of water jet machining (WJM) lies in the principle of water erosion. When a fast-moving jet of water, pressurized to extremely high levels, impacts a material surface, it erodes and removes the material through the sheer force of the water jet. For softer materials such as rubber, foam, and textiles, a pure water jet is sufficient for cutting and shaping. However, when working with harder materials like metals, glass, stone, or ceramics, the process incorporates abrasive particles (such as garnet or aluminum oxide) into the water stream. This enhanced method is known as Abrasive Water Jet Machining (AWJM). The addition of abrasives increases the cutting power, allowing the water jet to slice through even the most challenging materials with remarkable precision.

Are you wondering how water jet cutting compares to other machining methods? Explore our detailed sections below on use cases, benefits, and industry applications.

Abrasive Substances for Water Jet Machining

The effectiveness of abrasive water jet cutting depends heavily on the type and quality of abrasive materials used. Garnet is the most popular abrasive for industrial water jet cutting due to its optimal hardness, density, and low friability, which results in efficient cutting and minimal nozzle wear. Aluminum oxide is another common choice, especially when cutting extremely hard materials. Other abrasives such as glass beads and silica sand (SiO2) are used for specialized applications, like surface preparation or etching. The selection of abrasive particles directly impacts cut quality, speed, and cost-effectiveness, making it a vital decision for manufacturers and fabricators.

- Garnet Abrasive: Best for general-purpose precision cutting, minimal environmental impact.

- Aluminum Oxide: Ideal for high-strength and heat-resistant materials.

- Glass Beads: Suitable for light etching and finishing without aggressive material removal.

- Silica Sand: Used for cost-effective bulk cutting or surface cleaning operations.

Need help choosing the right abrasive for your water jet application? Contact our experts for tailored recommendations.

Principal Components of Water Jet Machines

A modern water jet cutting machine or waterjet system is a sophisticated assembly of high-pressure components designed for industrial precision and reliability. Understanding each part is essential for optimizing performance and ensuring consistent results in both prototyping and production environments.

Hydraulic Pump

The pump initiates the process by circulating water from the storage tank. It delivers water to the hydraulic intensifier at a preliminary low pressure (approximately 5 bars), which is then boosted to ensure consistent flow. Some systems employ a booster to raise the water pressure to around 11 bars before it enters the intensifier.

Hydraulic Intensifier

This vital component amplifies the water pressure dramatically, typically elevating it from 4 bar up to between 3,000 and 4,000 bar. The resulting high-pressure water stream is key to the cutting action, enabling the water jet to pierce and cut through tough materials with ease.

The Accumulator

The accumulator temporarily stores the high-pressure water, maintaining a ready supply for consistent cutting operations. It serves to buffer pressure fluctuations that could otherwise impact cut quality and process stability, ensuring smooth, uninterrupted machining.

Mixing Tube or Chamber

In abrasive water jet systems, the mixing chamber is where the abrasive particles are introduced into the pressurized water stream. The vacuum effect in this chamber ensures a uniform blend of water and abrasive for optimal cutting efficiency.

Control Valve

The control valve regulates the pressure and direction of the water jet, allowing precise adjustment during various stages of the cutting process. This enables operators to tailor the jet’s force and trajectory for specific materials or desired finishes.

Flow Regulator or Valve

This device manages the water flow, helping fine-tune cut quality, speed, and efficiency according to the job requirements.

Nozzle

The nozzle is a critical component that transforms the immense pressure of the water into kinetic energy, forming a high-velocity, focused jet. Nozzles are typically made from wear-resistant materials like diamond or ruby to withstand prolonged exposure and prevent erosion, ensuring long-lasting accuracy and performance.

Drain and Catcher System

After machining, this system collects debris and spent abrasive, filtering the water for reuse or safe disposal. Efficient debris management maintains a clean workspace, which is essential for both quality control and environmental compliance.

Types of Water Jet Cuts and Cutting Techniques

Water jet cutting systems offer remarkable flexibility, accommodating a variety of cutting profiles and geometries. Understanding the different types of water jet cuts is crucial when selecting the right solution for your manufacturing or fabrication needs.

Single Dimension (1D) Cutting

One-dimensional water jet cuts involve a stationary cutting head while the workpiece moves through the stream. This straightforward method is often used for trimming, slitting, and creating straight or parallel cuts. Examples include slitter applications in textiles, paper, or sheet materials. Both pure water and abrasive water jets can be used in single-dimension cutting, depending on material type.

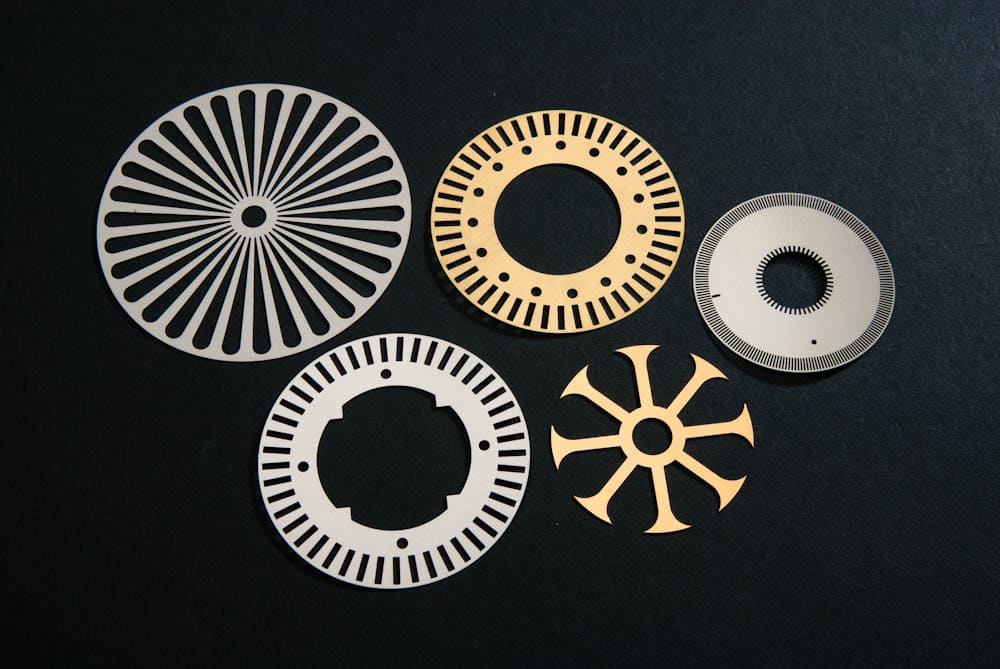

Two-Dimensional (XY) Cutting

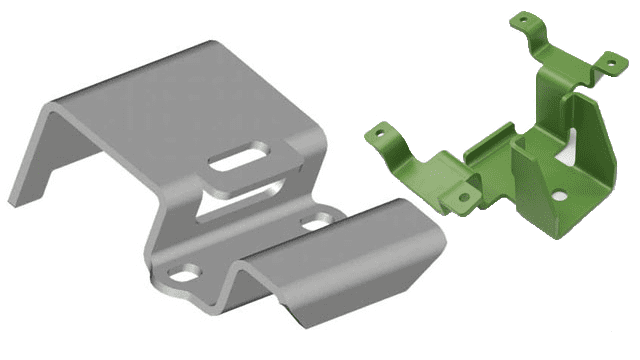

XY cutting introduces computer control (via CNC or PC software) to move the cutting head along the X and Y axes, producing intricate shapes, contours, and patterns. The machine supports the workpiece on water-filled slats to minimize splash and absorb energy. The Z-axis can be adjusted to accommodate variations in thickness. This is the most common application for water jet cutting in the fabrication of gaskets, automotive parts, architectural panels, and more.

Three-Dimensional (XYZ) Cutting

Three-dimensional water jet cutting adds movement along the Z-axis (vertical), enabling the creation of complex components and mechanical parts with varying depths or bevels. This capability is especially valuable in aerospace, automotive, and custom engineering projects. The workpiece remains stationary while the cutting head moves along all three axes, allowing for enhanced versatility and design complexity.

Four-Dimensional (XYZA) Cutting

Four-dimensional cutting incorporates rotational movement (A-axis), allowing the workpiece to rotate about the X-axis. This advanced technique is ideal for machining parts with holes, slots, or features on multiple faces. By flipping the workpiece automatically, the water jet can access and remove material from different sides, streamlining the production of intricate or multi-surface parts.

Specialized Cutting Techniques

- Bevel Cutting: Produces angled edges for weld prep or assembly.

- Multi-Head Cutting: Increases throughput by using several cutting heads simultaneously.

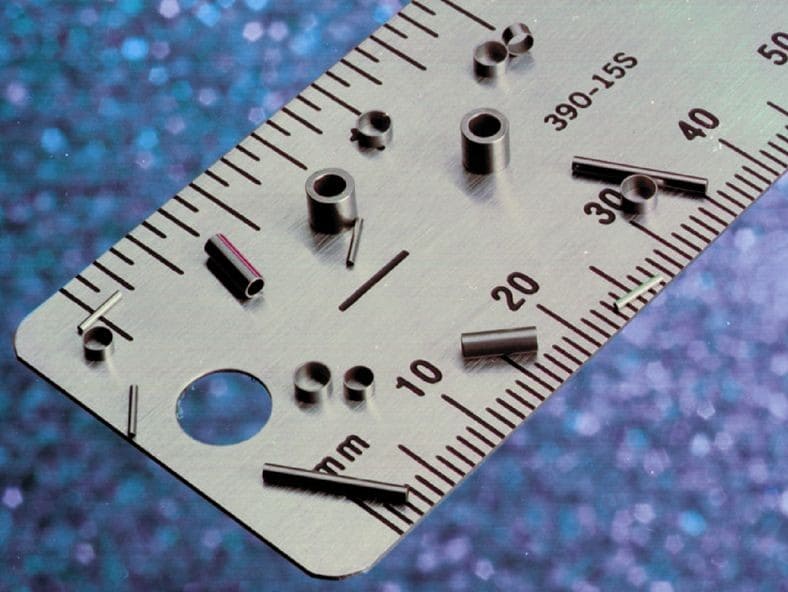

- Micro Waterjet Cutting: Delivers ultra-fine precision for electronics, jewelry, or medical devices.

Curious about which cutting technology suits your application? Ask our specialists for a tailored solution.

Advantages of Water Jet Machining

- Cold Cutting Process: Water jet cutting does not produce a heat-affected zone (HAZ), preserving material integrity and preventing thermal distortion, hardening, or warping.

- High Precision and Accuracy: Capable of achieving tolerances as tight as 0.005 inches, waterjet machining is trusted for fine-featured, complex patterns.

- Versatility: Cuts virtually any material—metals, composites, ceramics, glass, stone, plastics, rubber, foam, and even food—making it ideal for job shops, prototyping, and custom fabrication.

- Environmentally Friendly: The process uses only water and natural abrasives, generating no hazardous fumes, dust, or waste. Water is often recycled, and spent garnet can be repurposed for other applications.

- Minimal Tool Wear and Maintenance: With few moving parts and no direct contact with the workpiece, maintenance requirements are low and nozzle life is maximized.

- Clean Process: The water jet workspace is free from dust, smoke, and contaminants, supporting safe, clean operations in sensitive environments.

- Flexible Cutting Capabilities: Easily handles intricate designs, sharp corners, internal cutouts, and thick or layered materials.

- Efficient Material Utilization: The narrow kerf width and precise jet control minimize material waste, reducing production costs.

- Automation Ready: Compatible with CNC controls and CAD/CAM software for high-volume and repeatable manufacturing.

- Wide Range of Thicknesses: Can cut anything from thin foils and sheets to slabs several inches thick.

Want to compare water jet machining with laser cutting or plasma cutting? Explore our cutting technology comparison guide.

Applications of Water Jet Cutting in Industry

Water jet machining is a cornerstone of modern manufacturing, valued for its adaptability, speed, and exceptional cut quality. Its applications span a wide range of industries and use cases, serving both mass production and custom job orders.

- Automotive: Fabrication of gaskets, interior components, custom body panels, and prototype parts.

- Aerospace: Precision cutting of titanium, aluminum, composites, honeycomb structures, and engine components where heat distortion is unacceptable.

- Architecture and Construction: Artistic stone mosaics, glass panels, ceramic tiles, metal signage, and decorative inlays.

- Electronics: Micro waterjet cutting for circuit board substrates, enclosures, and delicate components.

- Medical Devices: Surgical tools, implants, and custom prosthetics requiring burr-free, contamination-free cuts.

- Food Processing: Hygienic cutting of frozen meats, seafood, pastries, and vegetables without cross-contamination or heat damage.

- Textiles and Leather: Automated pattern cutting for garments, footwear, and upholstery.

- Mining and Heavy Industry: Cutting and shaping of drill bits, wear plates, and reinforced structures.

- Signage and Art: Intricate metal, glass, or stone creations for branding, artwork, or functional designs.

- General Manufacturing: Rapid prototyping, tool making, fixture creation, and batch production for diverse sectors.

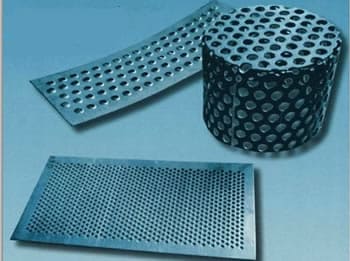

Material versatility: Water jet cutting excels with materials such as rubber, textiles, plastics, foam, leather, composites, tile, stone, glass, food, metals, and paper. Both WJM and AWJM are employed depending on whether the substrate is soft or hard.

Special processes: In addition to cutting, high-pressure water jets are used for cleaning, surface preparation, peening (to relieve residual stress), surgery, and even carving or etching.

Looking for real-world examples of water jet cutting in your industry? Browse our case studies section for detailed project highlights.

How to Choose the Right Water Jet Machining Company

Selecting a qualified water jet machining company is essential to achieving the best results for your project—whether you’re seeking custom fabrication, high-precision prototyping, or large-scale production. Here are some key factors to consider when evaluating water jet service providers:

- Industry Experience: Look for companies with a proven track record in your sector—be it aerospace, automotive, architectural, or medical applications.

- Technical Capabilities: Confirm the provider's ability to handle your desired materials, part sizes, thicknesses, and tolerances. Ask about their CNC technology, CAD/CAM integration, and multi-axis cutting options.

- Quality Assurance: Does the company follow ISO 9001 or other quality standards? What inspection and documentation processes are in place?

- Lead Times and Flexibility: Can the provider accommodate your project timeline, volume requirements, and design changes?

- Customer Service: Responsive communication, technical support, and the ability to provide design-for-manufacturability feedback are crucial.

- Cost and Value: While price is important, consider the overall value—precision, reliability, customer service, and post-cutting services like finishing or assembly.

How do you evaluate competing water jet machining companies? Start by comparing at least four providers using our curated water jet machining companies directory. Each profile highlights core capabilities, industry specializations, and contact details for requesting quotes. Use our simple RFQ form to send your project requirements to multiple firms at once—streamlining your vendor selection process.

Frequently Asked Questions About Water Jet Machining

What materials can be cut with water jet machining?

Water jet cutting is renowned for its ability to process virtually any material, including metals (steel, stainless steel, aluminum, titanium), composites, ceramics, glass, stone, plastics, rubber, foam, textiles, and even food products. The choice between pure water and abrasive water jet depends on material hardness and thickness.

How does water jet cutting compare to laser and plasma cutting?

Water jet cutting excels at cold processing, leaving no heat-affected zone or metallurgical changes in the workpiece. Unlike laser or plasma cutting, it can handle thick, reflective, or heat-sensitive materials. While lasers offer faster speeds for thin metals, water jet is superior for complex, multi-material jobs and thick sections.

Is water jet cutting environmentally friendly?

Yes. Water jet machining is considered a “green” manufacturing process. It uses water and natural abrasives, produces no hazardous fumes or dust, and enables water recycling and minimal waste generation.

How accurate is water jet machining?

Modern CNC water jet systems achieve tolerances as fine as 0.005 inches (0.13 mm), making them suitable for demanding industries like aerospace, electronics, and medical device manufacturing.

What is the typical lead time for water jet cutting services?

Lead times vary by project complexity and provider workload but are often faster than conventional machining due to rapid setup, minimal tooling, and high cutting speeds.

How do I get a quote or start a water jet cutting project?

To begin, prepare your project drawings (CAD files preferred), material specifications, and quantity requirements. Use our RFQ form to request quotes from multiple qualified water jet machining companies in your area.

Start Your Water Jet Machining Project Today

Whether you’re a manufacturer, engineer, designer, or procurement specialist, water jet machining offers unmatched flexibility, precision, and value for your production needs. From rapid prototyping to full-scale manufacturing, discover how water jet cutting can elevate your next project. Request a quote or contact our experts to discuss your requirements and receive personalized guidance.

Ready to learn more? Search our site for:

- Best water jet cutting services near me

- Water jet vs. laser cutting pros and cons

- Water jet cutting case studies and project examples

- Materials suitable for waterjet machining

- Water jet cutting FAQs

Boost your manufacturing productivity and achieve superior results with state-of-the-art water jet machining technology.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services