Waterjet cutting (water jet cutting), also known as hydro cutting, is an industrial process with which manufacturers can cut materials. The process uses a high-pressure stream of water or water combined with an abrasive substance. Read More…

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

At M.A.R.'s Engineering Company, Inc., we specialize in providing top-notch waterjet cutting services, catering to a multitude of industries. Our team of experts, armed with cutting-edge technology, can precisely cut a variety of materials, including metals, plastics, glass, ceramics, and more. No job is too big or too small for us; we've got the expertise and equipment to handle it all.

At Fruehauf Manufacturing, we take pride in delivering precision-engineered solutions through our expertise in water jet cutting. Our advanced capabilities allow us to cut a wide range of materials with exceptional accuracy, meeting the demands of industries that require intricate designs and high-quality finishes. By utilizing state-of-the-art water jet cutting technology, we offer a...

Barton International is a leading manufacturer and provider of abrasive blasting and waterjet cutting services. With more than 142 years of operation and five generations of the Barton family's leadership, we have cemented ourselves as one of the most trustworthy names in the industry. Today, we have forty stocking locations across North America and have expanded our product offering to more than ...

More Waterjet Cutting Companies

Applications

Waterjet cutting equipment is a versatile industrial tool used to create new shapes and modify existing ones in a wide range of parts and products. As a highly precise and flexible manufacturing solution, waterjet cutting is often used as a stand-alone fabrication method or as a complement to other cutting processes, such as plasma cutting, metal laser cutting, and traditional machining. This adaptability makes waterjet cutting an essential technology across many sectors seeking clean, accurate, and burr-free results.

Customers who seek waterjet cutting services and equipment span a broad spectrum of industries. Common applications include:

- Aerospace: Precision cutting of turbine blades, aircraft panels, brackets, and composites without thermal distortion.

- Automotive: Shaping and prototyping of body panels, engine parts, gaskets, and interior components.

- Industrial Equipment Fabrication: Production of machine frames, enclosures, gears, and wear-resistant parts.

- Electronics & Communications: Routing circuit boards, cutting shielding, and forming specialty enclosures.

- Metallurgy: Accurate cutting of hard and exotic metals for construction, mining, and processing equipment.

- Food Processing: Hygienic, precise slicing of food products, packaging, and conveyor components with zero risk of contamination.

- Art & Design: Artists, sculptors, and designers use waterjet cutting for intricate, geometrically complex sculptures and installations.

- Lumber Yards/Woodworking: Clean, splinter-free cutting of hardwood, engineered woods, and specialty veneers.

Whether you require custom components for aerospace, intricate signage, or rapid prototyping, waterjet cutting provides the accuracy and flexibility needed for both high-volume manufacturing and small-batch, custom projects.

Want to learn what materials waterjet cutting can process? Jump to Materials

Products Produced

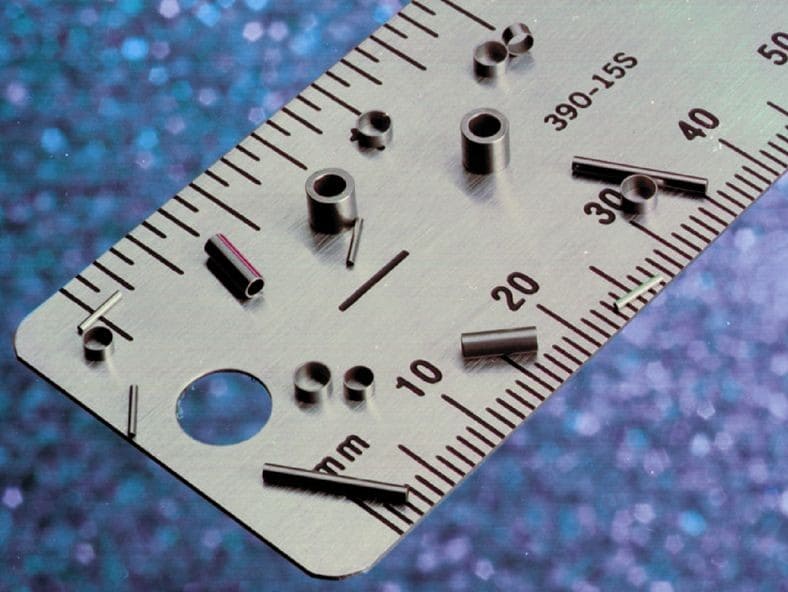

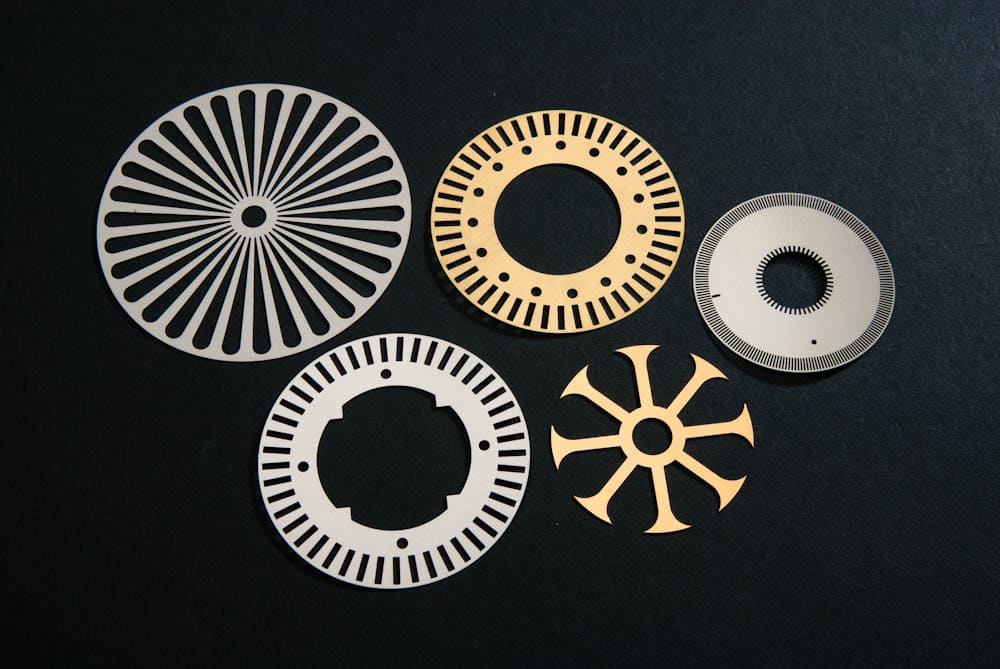

Through advanced waterjet cutting technology, manufacturers can produce a wide variety of precision parts and products with clean edges and complex geometries. Notable products created with waterjet cutting systems include:

- Interlocking hardware (bolts, gears, washers, fasteners)

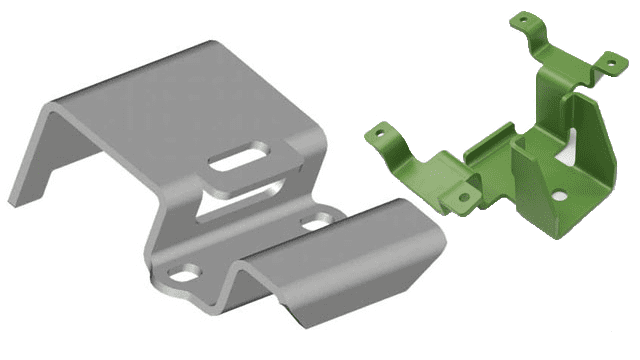

- Automotive parts (chassis components, interior panels, gaskets, seals)

- Electronic components (circuit boards, enclosures, connectors)

- Large assembly line products (machinery bases, sheet metal panels)

- Prototypes for engineering and design validation

- Architectural elements (decorative panels, custom tiles, glass inserts)

- Industrial gaskets and seals for piping and valves

- Custom signage and branding elements

- Artworks and intricate sculptures

Additionally, artists and designers utilize waterjet cutting to achieve high-precision cuts in metal, stone, glass, and other materials, enabling the realization of creative visions not possible with traditional tools.

Looking for examples of waterjet cut parts in your industry? Explore our directory of waterjet cutting companies to see industry-specific case studies and product galleries.

History

The evolution of waterjet cutting technology spans more than a century and reflects ongoing innovation in industrial manufacturing.

In the 1800s, water jets were first utilized in South Africa and New Zealand to wash away loose coal, rocks, and debris during mining operations, offering a safer alternative to manual clearing and reducing hazards such as falls, slides, and ricochets.

By the 1930s, water jets began to be used industrially for cutting. In the Soviet Union, high-pressure water cannons (exerting around 7,000 bars of pressure) were employed to cut large rocks. Meanwhile, in the United States, the Paper Patents Company in Wisconsin applied narrow water jets to cut paper, integrating moving nozzles into machines for continuous paper production. In 1956, Carl Johnson invented a waterjet cutting machine capable of slicing shapes into plastic, marking a pivotal advance in non-metal material processing.

While the Soviets excelled in cutting hard materials, American engineers faced challenges in processing anything beyond soft substrates until the late 1950s. In 1958, Bille Schwacha of North American Aviation successfully developed the first waterjet system capable of slicing hard materials, such as stainless steel, utilizing hypersonic liquid streams at 100,000 psi.

Further advancements included Philip Rice of Union Carbide’s 1962 pulsing water jet, which cut stones and metals using 50,000 psi. Optimal nozzle design for precise, concentrated jets emerged in the late 1960s, enhancing efficiency for stone and metal cutting.

The 1970s saw the integration of drill technology for ultra-high-pressure jets (up to 40,000 bars) and the introduction of abrasives, greatly expanding the range of machinable materials.

A breakthrough occurred in 1982 when Dr. Mohamed Hashish published foundational research on abrasive waterjet cutting (AWJ), furthering the technique’s effectiveness in processing hard materials. He received a patent for AWJ in 1987, solidifying its industrial relevance.

The 1990s ushered in the era of computer numerical control (CNC) integration. Dr. John Olsen and OMAX Corporation developed software for precision nozzle movement, merging CNC technology with waterjet cutters. This revolution enabled highly complex shapes with exceptionally tight tolerances, broadening the scope of waterjet machining.

In the early 2000s, the introduction of dynamic waterjets (zero taper jets) allowed for even greater accuracy and edge quality. The development of durable nozzles made from tungsten carbide composite extended equipment lifespan and reliability, supporting higher pressures and abrasive use.

Today, research continues with the development of micro abrasive waterjet technology, aiming for ultra-fine cutting in micro-manufacturing and electronics. Modern systems are increasingly efficient, environmentally friendly, and capable of tackling ever more challenging materials and design requirements.

Curious about the future of waterjet cutting? Contact our experts to discuss the latest innovations and how they can benefit your business.

Materials

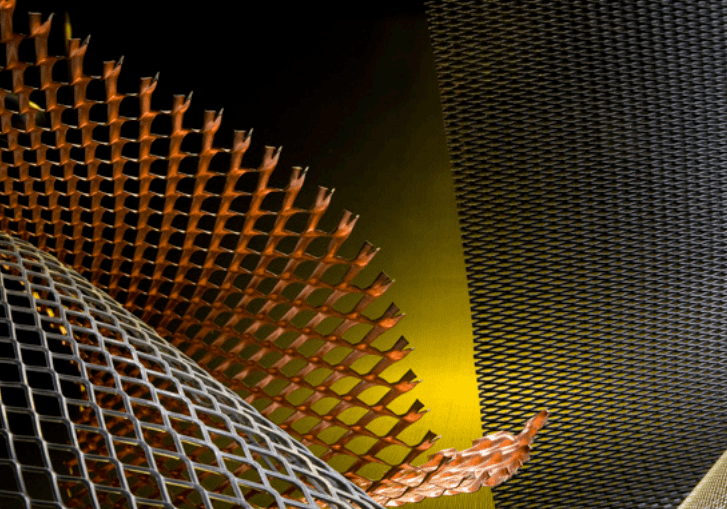

Waterjet cutters are valued for their ability to process a diverse array of materials, ranging from soft to extremely hard. Common materials that can be cut with waterjet technology include:

- Plastics (acrylic, polycarbonate, PVC, nylon, polyethylene)

- Rubber, foam, and composites

- Metals (steel, stainless steel, aluminum, copper, titanium, brass, bronze)

- Stone (granite, marble, slate, engineered stone)

- Glass (tempered, laminated, stained, bulletproof)

- Wood (hardwood, softwood, plywood, MDF, veneer)

- Ceramics (certain technical and engineered ceramics)

- Plexiglass and cork

- Specialty alloys and laminates

While waterjet cutting boasts remarkable versatility, there are some material limitations. For example, very fragile ceramics and glass may shatter under high-pressure water streams, while ultra-hard materials like diamond are not suitable for waterjet processing. Hydrophobic and moisture-sensitive substances may also be unsuitable for this method.

Not sure if your material can be cut with waterjet technology? Ask our team or explore our waterjet company directory for expert recommendations on material compatibility and best practices.

Process Details

The waterjet cutting process is a highly controlled and programmable operation, allowing for exceptional precision and repeatability in manufacturing.

How does waterjet cutting work? Before beginning, operators program the cutting equipment to achieve the desired pressure and cutting path. Typical waterjet systems operate between 30,000 and 90,000 PSI (pounds per square inch), but some specialized machines can reach pressures as high as 120,000 PSI for extremely tough or thick materials. Once setup is complete, the digital cutting pattern is executed by the machine.

- High-Pressure Pump: Water is pressurized using an intensifier or direct drive pump.

- High-Pressure Tubing: The pressurized water travels through stainless steel tubing to the cutting head.

- Nozzle and Mixing Chamber: Inside the nozzle, the water may be mixed with abrasive particles (such as garnet) for cutting hard materials. The aperture focuses the stream to a fine, high-velocity jet.

- Material Cutting: The focused stream exits the nozzle at supersonic speeds, eroding and cutting through the workpiece along the programmed path—achieving clean, burr-free edges and intricate shapes.

- Debris Collection: A catch tank or table below the cutting area collects spent water and abrasives for filtration and recycling.

Operators can adjust parameters such as pressure, nozzle speed, and abrasive flow to optimize cut quality for the material and geometry. CNC integration enables rapid design changes and seamless transition between jobs.

Do you need tight tolerances or intricate shapes? Discover how CNC waterjet cutting improves precision and efficiency for custom and complex projects.

Design

Waterjet cutting service providers can fully customize their equipment and process parameters to deliver optimal results for your unique application. Key elements that can be tailored include:

- Jet Stream Pressure: Adjusted to suit material hardness and thickness, ensuring clean cuts without damage.

- Abrasive Selection and Use: Abrasive type (e.g., garnet, aluminum oxide, silica sand) and quantity are chosen based on the material and desired edge finish.

- Aperture Size and Material: Nozzle orifice diameter (aperture) and material (often synthetic sapphire, ruby, or diamond) are selected for optimal stream focus and wear resistance.

- CNC Programming: Advanced software enables the creation of intricate paths, precise dimensions, and multi-axis cutting for three-dimensional components.

- Supporting Fixtures: Customized clamping, holding, and fixturing solutions prevent movement and ensure accuracy during cutting.

Operators may use lower pressure and omit abrasives when cutting fragile materials like ceramics or glass to prevent cracking or chipping. For tough and thick materials, abrasive waterjet cutting is the preferred method, blending fine abrasives with water in a high-pressure jet to increase cutting power.

Need advice on designing for manufacturability? Consult with a waterjet cutting engineer to optimize part geometry, minimize waste, and reduce production costs.

Machinery Used

Modern waterjet cutting machines are engineered for flexibility, high throughput, and precision. They are suitable for both small prototype batches and large-scale production runs. Key features and components include:

- Multi-Head Operation: Some machines are equipped with multiple cutting heads for simultaneous processing, increasing productivity and lowering per-part costs.

- CNC Control: Computer numerical control (CNC) systems guide the cutting head along programmed paths, ensuring repeatability and minimizing human error.

- Precision Nozzle: The nozzle, often called a mixing or focusing tube, directs the water and abrasives through the aperture. Typically made of stainless steel for durability.

- Nozzle Muff: A brush or sponge ring that minimizes splash and keeps the work area clean.

- High-Pressure Fittings: Engineered for safe operation, with side holes to safely disperse any leaks.

- Attenuator: Maintains consistent water pressure for uniform cutting performance.

- Apertures (Jewels): Made from synthetic sapphire, ruby, or diamond, these precisely shape the water stream for maximum accuracy.

- Catch Tank: Captures water and abrasive debris for recovery and environmental management.

- Software: CAD/CAM integration for fast job setup, nesting, and material optimization.

The integration of advanced software and electronics allows waterjet CNC programming to control every aspect of the cutting process, from nozzle speed to path complexity, delivering consistent, high-quality results with minimal waste.

Want to see how waterjet machinery compares to plasma or laser cutting machines? Browse company profiles and request a demo.

Variations and Similar Processes

Waterjet cutting technology encompasses several variations and is often compared to similar manufacturing processes. Understanding these options can help you select the right approach for your application.

- Abrasive Waterjet Cutting: Also known as abrasive jet machining, this method mixes water with abrasive particles (such as garnet, diamond, or sand) to cut hard materials including metals, stone, brick, and marble. It is ideal for applications demanding tight tolerances and smooth finishes on tough substrates.

- Abrasive Flow Machining (AFM): A secondary process for refining difficult-to-reach or internal surfaces. It provides burr removal, crack elimination, polishing, and smoothing for complex components such as dies, molds, and engine parts.

- Pure Waterjet Cutting: The original waterjet process, which uses only water (no abrasives). It is best suited for cutting softer materials such as foam, rubber, textiles, paper, and food products without risk of contamination or thermal damage.

- CNC Waterjet Cutting: Combines waterjet technology with CNC programming for highly accurate, repeatable, and complex cutting operations. Used for intricate designs, rapid prototyping, and multi-axis machining.

How do waterjet cutting and laser cutting compare?

- Waterjet cutting is a cold process, eliminating heat-affected zones and material warping associated with lasers.

- Waterjet can cut thicker materials and a wider range of substrates than most laser cutters.

- Laser cutting offers faster speeds for thin metals and plastics, but is limited in material compatibility and cut thickness.

Still deciding between waterjet, plasma, or laser cutting? Request a process comparison from our team or review industry guides for in-depth analysis of each method’s strengths, limitations, and cost profiles.

Benefits

Waterjet cutting services are highly valued for their unique combination of advantages, making them the preferred choice for a wide range of industrial and commercial applications:

- Precision: Waterjet cutting produces parts with exceptionally smooth, accurate edges and tight tolerances, even on intricate designs or thick materials. No burrs, thermal distortion, or rough edges, especially when paired with CNC control.

- Cold-Cutting: As a cold process, waterjet cutting does not generate heat, preventing issues such as warping, discoloration, hardening, or material degradation. This makes it ideal for heat-sensitive materials, composites, and stacked cutting of multiple sheets.

- Material Reclamation: Efficient use and recycling of water and abrasive media reduce waste, lower costs, and promote sustainability. Many waterjet systems include filtration and reclamation systems for closed-loop operation.

- Efficiency: Low-energy consumption, fast setup, and rapid cutting speeds improve throughput and reduce manufacturing lead times. Waterjet systems can operate for extended hours with minimal maintenance.

- Cost-Effectiveness: Low material waste, reduced tooling costs, and minimal secondary finishing (no deburring, grinding, or sanding required) keep per-part costs competitive, especially for short runs and prototyping.

- Worker Safety: No sharp blades, no toxic fumes, and automated operation reduce the risk of workplace accidents or injuries, making waterjet facilities safer for operators.

- Adaptability: Quick changeover between jobs, compatibility with a broad range of materials, and the ability to cut complex shapes make waterjet cutting highly versatile for manufacturers responding to changing market demands.

- Environmental Friendliness: Waterjet cutting uses no hazardous chemicals, generates little airborne dust, and can employ recycled water, reducing environmental impact when compared to traditional cutting methods.

Need a cost estimate or want to see a sample part? Contact a listed waterjet service provider to request a quote or a demonstration of their capabilities.

Selecting a Service Provider

Choosing the right waterjet cutting company is essential to ensuring the success of your project—whether you need rapid prototyping, high-volume production, or custom one-off parts. Here are the most important factors to consider when evaluating suppliers:

- Industry Experience: Does the company have expertise with your specific materials, part designs, and tolerances?

- Equipment Capabilities: Can they handle the size, thickness, and complexity your project demands? Do they offer abrasive, pure, and CNC waterjet cutting?

- Quality Assurance: What certifications, inspection processes, and quality control measures are in place?

- Turnaround Time: Can they meet your deadlines, deliver rush orders, or accommodate just-in-time manufacturing?

- Customer Support: Will you have access to engineering support, material selection guidance, and post-delivery services such as installation, parts replacement, or troubleshooting?

- Pricing and Value: Are their quotes competitive, transparent, and aligned with your budget? Do they offer value-added services such as nesting optimization, design review, or assembly?

- Geographic Reach: Do they serve your location or offer nationwide/international delivery?

How to choose a waterjet cutting supplier:

- Review our list of waterjet cutting companies and filter by industry, capabilities, and location.

- Select three or four providers that fit your project requirements.

- Contact each company for a detailed quote, specifying your material, part dimensions, tolerances, and desired turnaround.

- Compare their services, lead times, quality assurances, and customer reviews.

- Choose the provider best suited to your technical needs and business goals.

Ready to get started? Use our directory to find experienced, trusted waterjet cutting service providers and request a custom quote today!

If you have questions about waterjet cutting applications, materials, or process selection, our team is here to help. Explore our site for more resources, technical guides, and expert insights.

What industries commonly use waterjet cutting?

Waterjet cutting is widely used in industries such as aerospace, automotive, industrial equipment fabrication, electronics, metallurgy, food processing, art and design, and woodworking. Its versatility and ability to cut without heat or burrs make it ideal for a wide range of applications and materials.

What materials can be cut using waterjet technology?

Waterjet cutters can process plastics, rubber, foam, composites, metals (including steel, aluminum, copper, titanium, and brass), stone, glass, wood, ceramics, plexiglass, cork, and specialty alloys. Some very fragile ceramics, thin glass, and materials like diamond or moisture-sensitive substances may not be suitable.

How does waterjet cutting work?

Waterjet cutting uses a high-pressure pump to force water through a small nozzle, sometimes mixed with abrasive particles, creating a focused jet that cuts materials by erosion. Computer numerical control (CNC) systems guide the jet to achieve complex shapes with clean edges and tight tolerances.

What are the main benefits of waterjet cutting?

The main benefits include precision, burr-free and heat-free cutting, adaptability to many materials, efficiency, material reclamation, environmental friendliness, minimal waste, cost-effectiveness, and enhanced worker safety.

What types of products can be produced with waterjet cutting?

Products made with waterjet cutting include interlocking hardware, automotive parts, electronic components, large machinery panels, engineering prototypes, architectural elements, industrial gaskets, custom signage, and intricate artworks or sculptures.

What are the main types of waterjet cutting processes?

There are two main types: pure waterjet cutting, which uses only water and is ideal for soft materials, and abrasive waterjet cutting, which adds abrasive media for cutting hard materials such as metals and stone. CNC waterjet cutting allows for complex, repeatable cuts.

How do I select a waterjet cutting service provider?

Consider a provider’s industry experience, equipment capabilities, quality assurance, turnaround time, customer support, pricing, value-added services, and geographic reach. Request quotes and compare their services, quality, and customer reviews before making a choice.

What factors can be customized in the waterjet cutting process?

Key customizable factors include jet stream pressure, abrasive type and quantity, nozzle aperture size and material, CNC programming for complex paths, and fixturing solutions to secure the workpiece. Adjustments are made based on material type, thickness, and desired finish.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

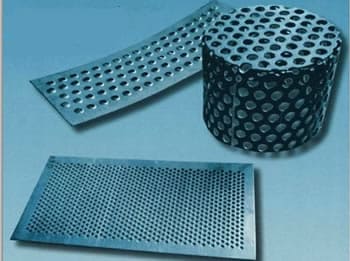

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services