In the manufacturing process known as “water jet cutting,” several materials are cut and shaped using high-pressure water jets delivered by pressurizing pumps that deliver a supersonic stream of water. In water jet cutting, a tiny, precise nozzle is used to project water pressurized to 392 MPa. Read More…

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

At M.A.R.'s Engineering Company, Inc., we specialize in providing top-notch waterjet cutting services, catering to a multitude of industries. Our team of experts, armed with cutting-edge technology, can precisely cut a variety of materials, including metals, plastics, glass, ceramics, and more. No job is too big or too small for us; we've got the expertise and equipment to handle it all.

At Fruehauf Manufacturing, we take pride in delivering precision-engineered solutions through our expertise in water jet cutting. Our advanced capabilities allow us to cut a wide range of materials with exceptional accuracy, meeting the demands of industries that require intricate designs and high-quality finishes. By utilizing state-of-the-art water jet cutting technology, we offer a...

Barton International is a leading manufacturer and provider of abrasive blasting and waterjet cutting services. With more than 142 years of operation and five generations of the Barton family's leadership, we have cemented ourselves as one of the most trustworthy names in the industry. Today, we have forty stocking locations across North America and have expanded our product offering to more than ...

More Waterjet Cutting Companies

Comprehensive Guide to Water Jet Cutting: Types, Applications, and Selecting the Best Waterjet Cutting Services

Water jet cutting is a highly versatile cutting process that harnesses the power of high-pressure water, sometimes combined with abrasives, to slice through a wide variety of materials with remarkable precision. As the water exits the nozzle, it reaches speeds up to three times the speed of sound, allowing for efficient and accurate cutting of both soft and hard materials. This advanced manufacturing technology has revolutionized industries such as aerospace, automotive, metal fabrication, stone and tile processing, and electronics manufacturing. Whether you're seeking a solution for intricate designs, delicate materials, or heavy-duty industrial applications, understanding the types, capabilities, and benefits of water jet cutting can help you choose the right process and service provider for your needs.

What Is Water Jet Cutting?

Water jet cutting, also known as waterjet machining or waterjet cutting technology, is a cold cutting process that uses a high-pressure stream of water—sometimes with added abrasives—for precision cutting of various materials. The process is valued for its ability to cut materials without generating heat-affected zones (HAZ), preserving the structural integrity and material properties of the workpiece. Water jet cutting is widely utilized in industries where precision, speed, and flexibility are critical. Looking to learn more about how waterjet cutting works and what materials it can handle? Read on for an in-depth exploration.

Types of Water Jet Cutters

Pure Water Jet Cutters

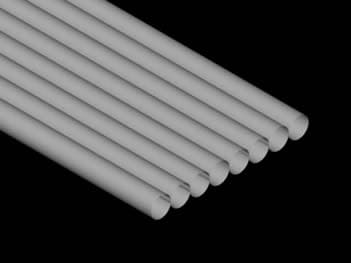

Pure water jet cutters are designed specifically for cutting soft, non-metallic materials without the use of abrasives. In these systems, a high-pressure pump pushes water through a small orifice, creating a concentrated, fast-moving jet capable of slicing through materials such as:

- Wood and composite woods

- Plastics (including polyethylene, PVC, and acrylics)

- Foam and rubber

- Paper and cardboard

- Textiles and leather

- Food products (for hygienic, precise cuts in food processing)

This process is especially popular in industries where material integrity and cleanliness are paramount, such as food processing, packaging, and electronics insulation cutting. Because it is a cold cutting process, there is no risk of thermal distortion or chemical contamination, making pure water jet cutting ideal for sensitive materials. Wondering if pure water jet cutting is right for your project? Ask us about optimal applications for soft materials.

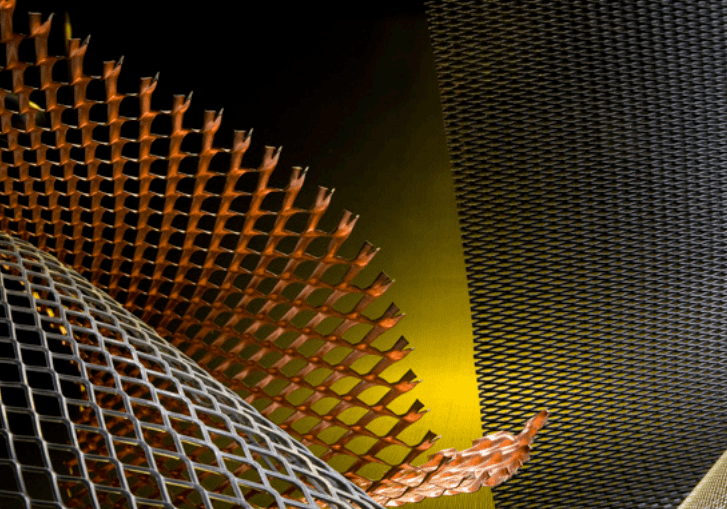

Abrasive Water Jet Cutters

When it comes to cutting harder, denser materials, abrasive water jet cutters are the solution of choice. These systems introduce a fine abrasive material—typically garnet, aluminum oxide, or silicon carbide—into the high-velocity water stream. The abrasives provide additional cutting power, enabling the jet to erode and slice through tough substrates such as:

- Stainless steel and carbon steel

- Aluminum, titanium, and other metals

- Stone, marble, granite, and ceramics

- Glass and composites (including laminates and fiberglass)

- Concrete and advanced engineered materials

Abrasive water jet cutting is renowned for its ability to produce smooth, precise edges and complex shapes with minimal burring or need for secondary finishing. This makes it a preferred method in aerospace manufacturing, metal fabrication, architectural stonework, and automotive prototyping. Curious about the best abrasive materials for your job or how abrasive waterjet compares to plasma cutting or laser cutting? See our comparison guide below or contact us for tailored advice.

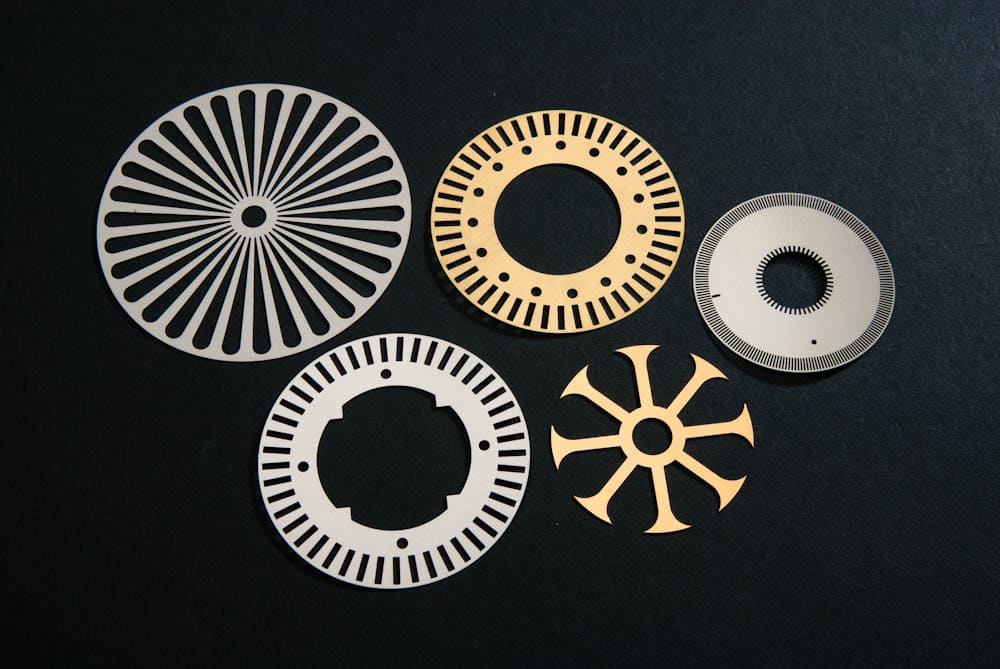

CNC Water Jet Cutters

For the ultimate in precision and automation, CNC (Computer Numerical Control) water jet cutters offer programmable, multi-axis movement for complex part geometries and high repeatability. These advanced machines can be configured in 3-axis, 4-axis, or even 5-axis setups, giving them the ability to perform intricate cuts, bevels, and contours across a range of materials. Typical applications include:

- Custom metal fabrication for aerospace and defense

- Precision automotive components

- Architectural and artistic metalwork

- Electronics and circuit board prototyping

- Medical device manufacturing

With CNC water jet technology, manufacturers benefit from high production speeds, minimal material waste, and the capability to process prototypes as well as large production runs. Software-driven controls enable rapid changeover between jobs and exceptional design flexibility—making CNC water jet cutting an industry standard for custom and high-value parts. Interested in learning how CNC water jet cutting can optimize your production workflow? Contact our experts for a process evaluation.

High-Pressure Water Jet Cutters

High-pressure water jet cutters utilize advanced intensifier pumps to achieve pressures of up to 90,000 psi or more, allowing for rapid and precise cutting of even the most challenging materials. The cutting head often incorporates corundum components—such as synthetic rubies and sapphires—due to their exceptional hardness, durability, and chemical resistance. These cutters are commonly used for:

- Cutting thick metals and alloys

- Large format stone and tile

- Heavy-duty glass fabrication

- Demolition and industrial recycling

The combination of high pressure and precise engineering minimizes water usage and maximizes cutting efficiency, helping manufacturers achieve tight tolerances and high throughput. Need more information about high-pressure water jet cutting performance or how it can reduce cycle times in your shop? Explore our technical resources or request a detailed consultation.

Key Benefits and Advantages of Water Jet Cutting

- Unmatched Material Versatility: Water jet cutting can process virtually any material—from soft foams to hardened steel—without regard for material hardness. This makes it an invaluable tool for custom manufacturing, prototyping, and job shops handling diverse projects.

- Cold Cutting Process: Unlike laser cutting or plasma cutting, water jet cutting does not create heat-affected zones (HAZ) or thermal distortion. This preserves the base material's mechanical and structural properties and eliminates the risk of warping, especially in metals and composites.

- Environmentally Friendly Manufacturing: Water jet cutting produces no hazardous fumes, toxic gases, or dangerous particulates. The process uses pure water and, in abrasive systems, natural minerals like garnet, meaning waste streams are generally non-toxic and easily filtered or recycled. Curious about sustainable manufacturing practices? See our green manufacturing FAQ.

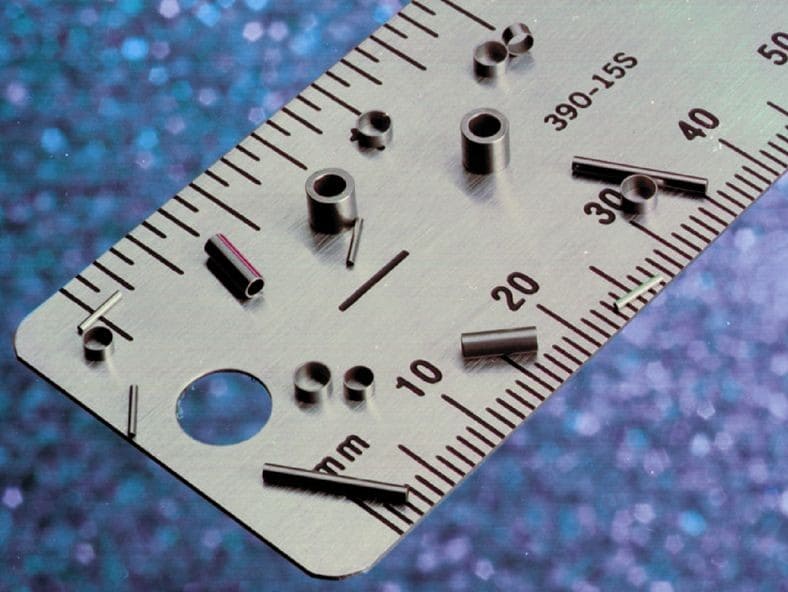

- Exceptional Precision and Edge Quality: Capable of producing intricate shapes and features with tolerances as fine as ±0.001 inches, water jet cutting is ideal for applications demanding high accuracy and minimal finishing.

- Cost Efficiency and Productivity: Water jet cutting machines can cut multiple layers or stacked materials in a single pass, increasing throughput and reducing per-part costs. The process requires minimal setup and tooling time, making it suitable for both small batch and mass production scenarios.

- Customizable Table Sizes: Water jet cutting systems are available in a range of table sizes to accommodate large sheets, long panels, or intricate small parts. Whether you need to cut massive slabs of stone or delicate electronic components, there is a water jet solution for you.

- No Tool Wear or Material Deformation: Since the process is non-contact and does not use mechanical tools, there is minimal wear and no risk of contaminating the workpiece with foreign materials.

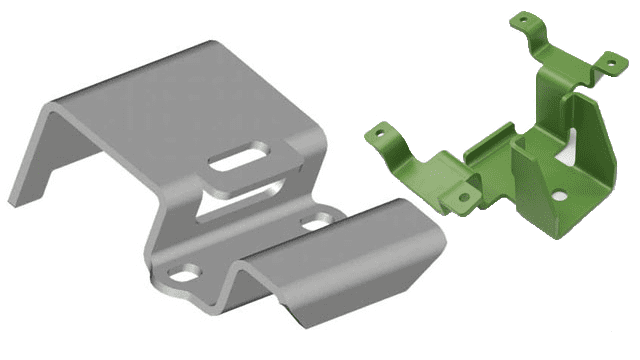

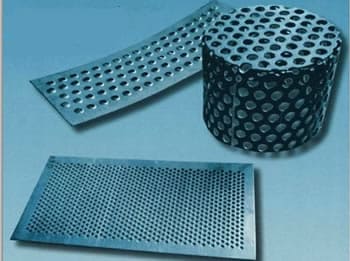

Common Applications of Water Jet Cutting

Water jet cutting technology is used across a broad spectrum of industries. Here are just a few of the most common applications:

- Aerospace: Cutting titanium, aluminum, composites, and specialty alloys for structural components, engine parts, and prototypes.

- Automotive: Manufacturing custom gaskets, interior trim, chassis panels, and prototyping new designs.

- Architecture and Construction: Shaping stone, marble, glass, and metals for decorative facades, flooring, and signage.

- Metal Fabrication: Producing brackets, panels, enclosures, gears, and machine components from steel, copper, brass, and aluminum.

- Electronics: Cutting insulation, circuit boards, and delicate substrates for electronic assembly and prototyping.

- Medical Devices: Precision cutting of metals, plastics, and composites for surgical instruments, implants, and laboratory equipment.

- Food Processing: Hygienic slicing of meats, vegetables, and prepared foods without contamination or crushing.

Are you looking for water jet cutting services for a unique application, or do you need help selecting the right machine for your material? Get in touch with our specialists for tailored recommendations.

Comparing Water Jet Cutting to Other Cutting Technologies

When selecting a cutting process, it’s important to compare the strengths and limitations of water jet cutting relative to laser cutting, plasma cutting, and traditional machining. Here are some key decision factors:

- Material Compatibility: Water jet can cut virtually any material, whereas laser and plasma are generally limited to metals and select non-metals.

- Edge Quality: Water jet produces smooth, burr-free edges with minimal need for secondary processing. Plasma and laser may require post-processing for high-precision work.

- Heat Effects: Only water jet is truly a cold cutting process, eliminating HAZ. Laser and plasma generate significant heat, which can affect material properties.

- Thickness Capability: Water jet can cut materials up to 12 inches thick or more, while lasers and plasma are best suited to thinner materials.

- Environmental Impact: Water jet cutting is cleaner and safer for operators, with little airborne dust or fumes. Plasma and laser may require additional ventilation or filtration.

Still unsure which cutting process is right for your needs? Check our FAQ or reach out for a custom process comparison.

What to Consider When Choosing a Waterjet Cutting Company

Choosing the right waterjet cutting service provider is crucial for ensuring quality, efficiency, and cost-effectiveness for your project. Here are key factors to evaluate:

- Technical Capabilities: Does the company offer pure water, abrasive, and CNC water jet cutting? What are their maximum cutting thicknesses and tolerances?

- Material Expertise: Are they experienced with your specific material—be it metals, composites, glass, stone, or plastics?

- Turnaround Time: Can they meet your production schedule for prototypes, short runs, or volume orders?

- Quality Assurance: What inspection processes and certifications (such as ISO 9001 or AS9100) do they hold?

- Customer Service: Do they provide clear communication, design support, and post-processing services if required?

To ensure you choose the best waterjet cutting partner, we recommend comparing at least four companies using our waterjet cutting company directory. Each profile details the provider's experience, equipment, and specializations. Use our patented website previewer to quickly review capabilities, then submit your project details using our streamlined RFQ (Request for Quote) form to contact multiple companies at once.

Frequently Asked Questions (FAQ) About Water Jet Cutting

How accurate is water jet cutting?

Modern water jet cutters can achieve tolerances as tight as ±0.001 inches, depending on the machine, material, and cut geometry. This makes them ideal for precision manufacturing and high-value component fabrication.

What materials cannot be cut with a water jet?

While water jet cutting is incredibly versatile, it is not suitable for certain types of tempered glass (which may shatter unpredictably) or materials that absorb water and swell during processing. For most metals, plastics, ceramics, and composites, water jet is an excellent choice.

How thick can a water jet cut?

Typical water jet systems can cut materials up to 12 inches (300 mm) thick, depending on the material type and machine configuration. For extremely thick or dense materials, consult with your provider for feasibility.

Is water jet cutting environmentally friendly?

Yes. Water jet cutting produces no hazardous emissions, and waste abrasives can often be recycled. The process uses less energy than many thermal cutting methods and supports sustainable manufacturing initiatives.

How does water jet cutting compare to laser or plasma cutting?

Water jet is a cold cutting process, avoiding heat-affected zones and enabling the cutting of heat-sensitive or reflective materials. It offers superior edge quality and versatility but may have slower cutting speeds for thin metals compared to laser or plasma. For a detailed process comparison, contact our technical team.

Get Started: Find a Water Jet Cutting Service or Machine

Ready to take the next step? Whether you need a single prototype or high-volume production, our network of top-rated waterjet cutting companies can help you achieve precise, cost-effective results. Browse our directory, review company profiles, and request a quote today. Not sure which service or machine is right for you? Contact our experts for a personalized consultation and get answers to your specific questions about water jet cutting applications, equipment, and best practices.

For more technical articles, industry insights, and waterjet cutting resources, explore our blog or sign up for updates. Your next project deserves the power and precision of advanced water jet cutting technology!

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services