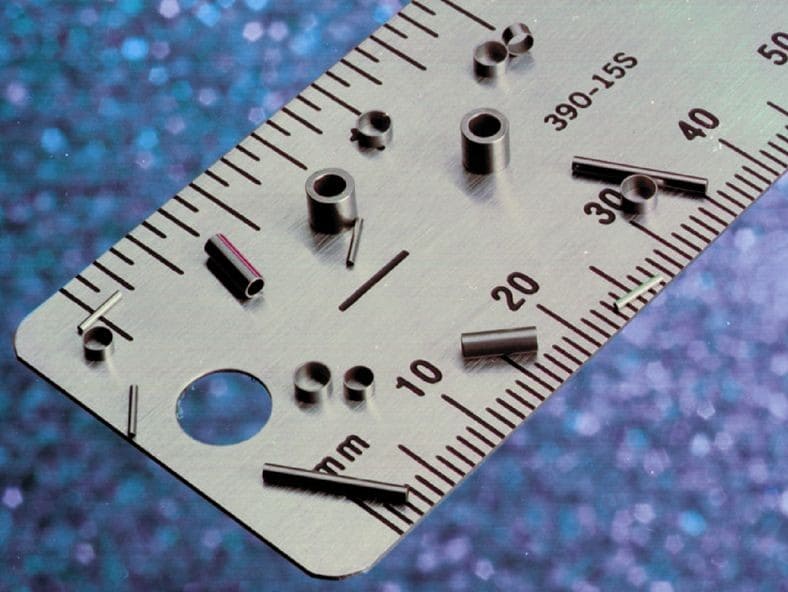

In the manufacturing process known as “water jet cutting,” several materials are cut and shaped using high-pressure water jets delivered by pressurizing pumps that deliver a supersonic stream of water. In water jet cutting, a tiny, precise nozzle is used to project water pressurized to 392 MPa. Read More…

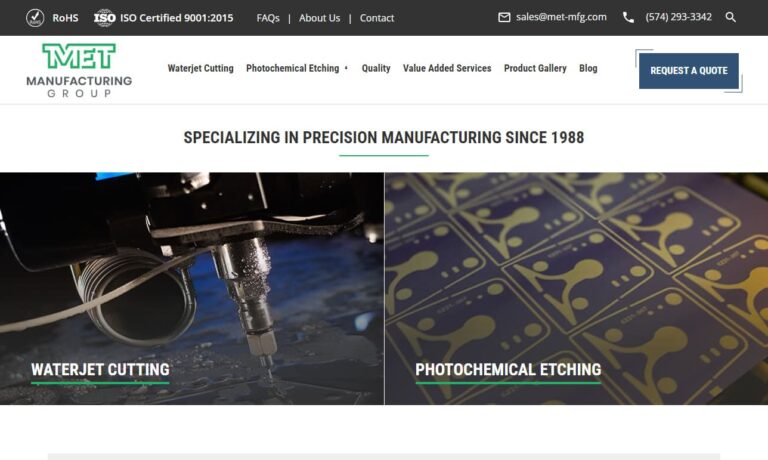

Since 1988, MET Manufacturing Group, LLC has been a trusted provider of quality waterjet cutting services. Our water jet equipment is great for prototyping, fast and reliable for production, and can quickly change from job to job. Material cutting capabilities include plastic, rubber, copper, aluminum, titanium, and many more. Tolerances for certain applications can be held at +- .001". Contact...

At A & D Rubber Products Company, we take pride in offering industry-leading water jet cutting services designed to meet the diverse needs of our clients. Using state-of-the-art water jet technology, we are able to cut through a wide variety of materials with precision and efficiency. From rubber to plastics, our capabilities ensure smooth, clean edges without compromising the integrity of the...

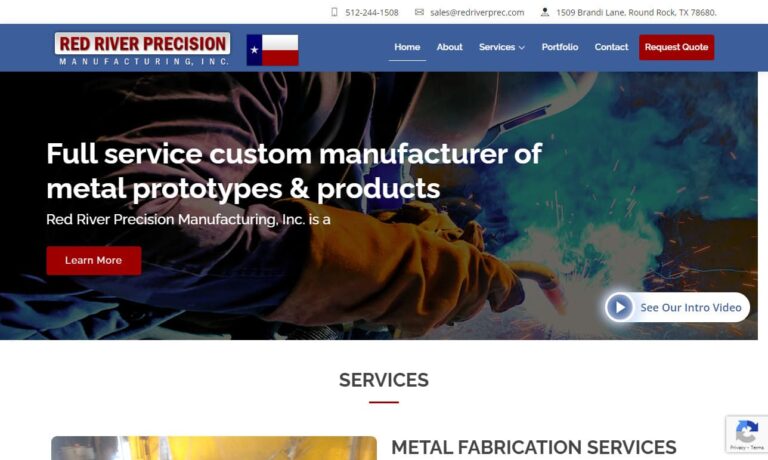

At Red River Precision Mfg., we are dedicated to providing advanced water jet cutting solutions that meet the highest standards of precision and quality. Our expertise lies in harnessing the power of water jet technology to cut through a wide range of materials with exceptional accuracy, from metals to plastics and everything in between. This technology allows us to achieve intricate and clean...

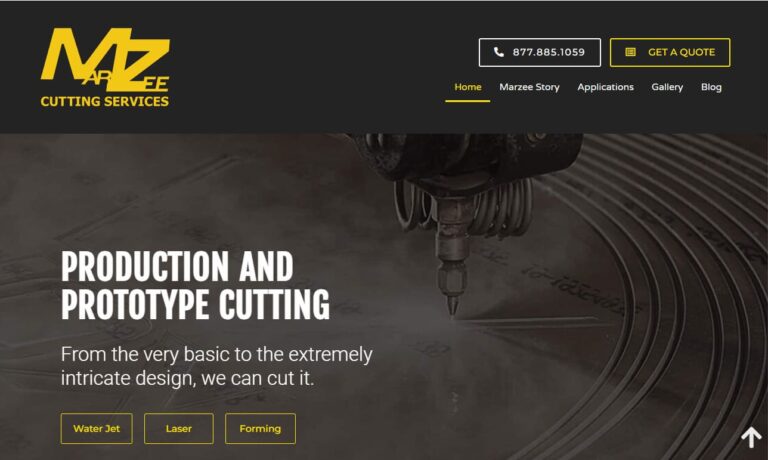

At MarZee Cutting Services, we specialize in precision water jet cutting, providing highly accurate solutions for a wide range of materials. Our cutting-edge technology allows us to work with metals, plastics, composites, and more, ensuring clean, detailed cuts without compromising the integrity of the material. With our versatile water jet systems, we can handle intricate patterns and complex...

At Precision Wire EDM Service Inc., we specialize in delivering high-precision cutting solutions that cater to a wide range of industries. With our expertise in wire EDM and water jet cutting, we have established ourselves as a trusted partner for intricate and demanding projects. Our water jet cutting capabilities allow us to handle diverse materials with remarkable accuracy, providing clean...

More Waterjet Cutting Companies

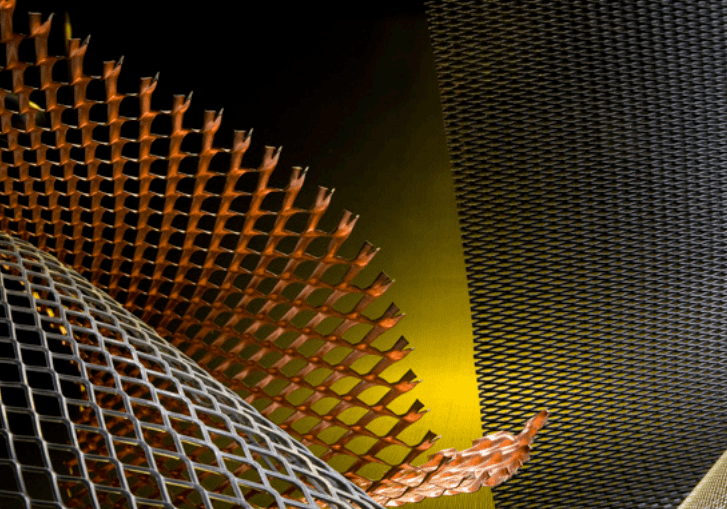

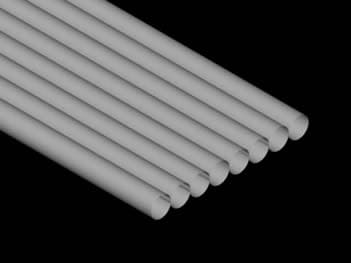

The water reaches three times the speed of sound as it exits the nozzle. Soft materials, including wood, plastics, foam, paper, and rubber, are intended for soft water jet cutting, which uses water as the cutting medium. An abrasive is added to a water stream to create more aggressive cutting when needed for hard materials, such as titanium, stainless steel, aluminum, glass, ceramic material, and concrete.

Types of Water Jet Cutters

Pure Water Jet Cutters

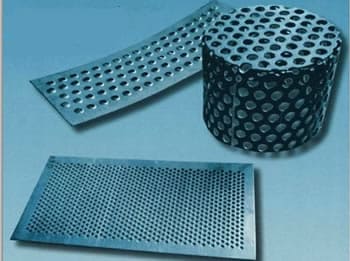

Pure water jet cutters can cut soft materials without using abrasives. A mixing chamber or a nozzle is absent from a water jet cutter made specifically for this use. Instead, a high-pressure pump pushes pressurized water out of an aperture to make accurate cuts on the workpiece. However, both techniques can be used with most industrial cutting instruments that utilize water jet technology.

Comparatively speaking, the pure water jet cutting procedure is less invasive than abrasive water jet cutting. Additionally, the jet stream is incredibly fine and exerts no additional strain on the workpiece. Softer materials, including foam, felt, wood, rubber, food, and thin plastics, are perfect for pure water jet cutting.

Abrasive Water Jet Cutters

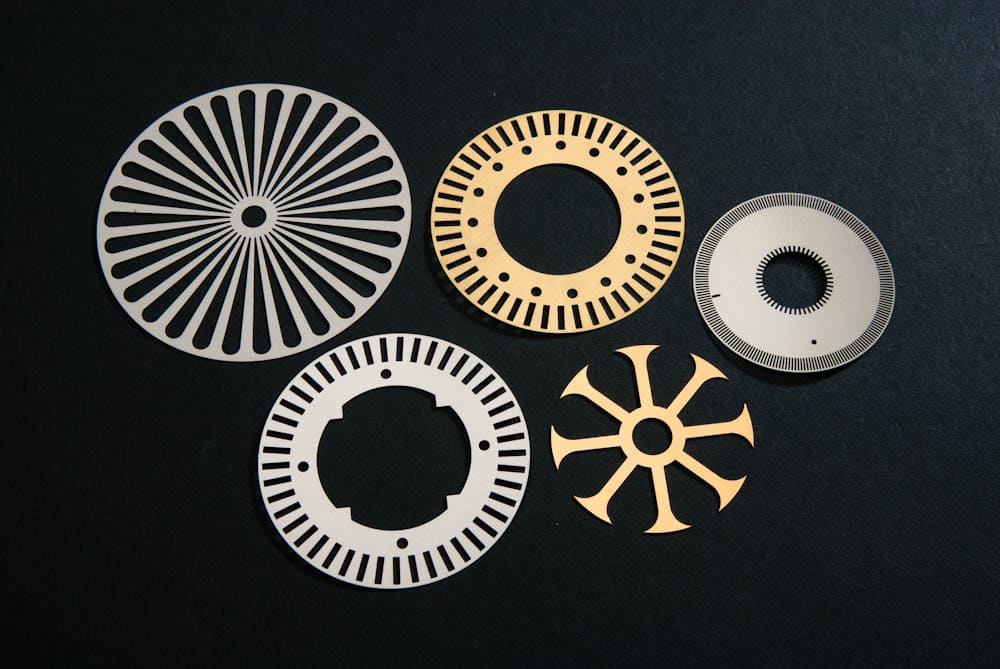

The abrasive water jet cutting core uses a high-pressure stream of water mixed with an abrasive. It blasts and erodes the workpiece to eliminate debris, burrs, and particulates. The cutting particles used in abrasive water jet cutting are extremely tiny and applied at high velocity. This procedure cuts and shapes thin, brittle, and hard materials. Abrasive jet machining cuts intricate shapes and creates precise, even edges.

CNC Water Jet Cutters

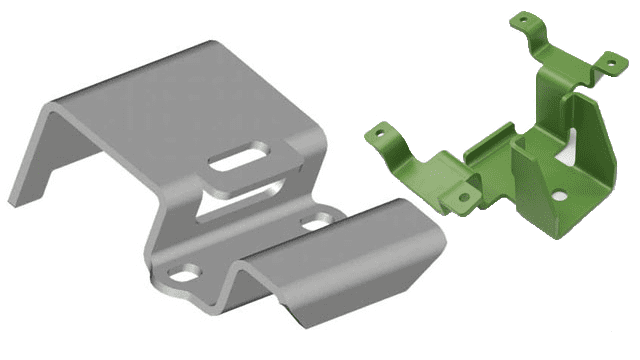

High-pressure water is also used in CNC water jet cutting, but these machines are programmed to perform several tasks in a single pass. The primary application for a CNC water jet cutter is to shape and cut material too delicate for high-temperature operations. Cutting, shaping, deburring, reaming, and honing are some of the functions a CNC water jet cutting machine performs. Most CNC water jet cutting devices have three axes and work along the X, Y, and Z axes, with the X axis moving left to the right, the Y moving front to back, and the Z moving up and down. There are also four- and five-axes models available.

High-Pressure Water Jet Cutters

High-pressure water jet cutters dramatically increase the pressure of pure water by using intensifiers, allowing them to shape and mold soft materials without leaving water behind. Hydraulic pumps use the power of the water to convert it into mechanical energy, thereby intensifying the water flow. The cutting head significantly improves high-pressure water jet cutting using corundum components, which are different types of rubies and sapphires. Corundum is incredibly strong, durable, and stable. It is the world's second-hardest mineral and is unaffected by acids.

Advantages of Water Jet Cutting

- Water jet cutting has infinite applications because it can cut any substance, regardless of its hardness. Water jet cutting slices materials without affecting their integrity or mechanical qualities. Thin materials can be chopped and stacked for improved efficiency to boost productivity and further minimize expenses. Water jet cutting machines can come with various table sizes to accommodate various workpiece sizes.

- Every manufacturer and sector is considering going green. The consequences of environmental protection measures have impacted other cutting techniques besides water jet cutting. Unlike most cutting techniques, water jet cutting does not produce waste, particulate matter, or contaminants. A water jet cutter produces no poisonous substances, hazardous waste, or toxic gasses. It makes use of pure water that has been supplemented with organic abrasives. The discharge of leftover material won't harm the environment from the process.

- A water pump and cutting tool create a high-velocity water stream that travels three times the speed of sound during the water jet cutting process. Any cut in any material can be made using the same parts. Due to its lack of complexity, water jet cutting is a cost-effective and economical production process for both 2D and 3D products.

Choosing the Proper Waterjet Cutting Company

To make sure you have the most beneficial outcome when selecting a waterjet cutting company, it is important to compare at least 4 companies using our directory of waterjet cutting companies. Each waterjet cutting company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each waterjet cutting business website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple waterjet cutting companies with the same form.

Broaching

Broaching CNC Machining

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

Metal Fabrication Perforated Metals

Perforated Metals Screw Machine Products

Screw Machine Products Metal Stampings

Metal Stampings Sheet Metal Fabrication

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services