Edge quality is probably the most important factor to consider when it comes to water jet cutting, and this is directly related to the speed of the cut. That is why quotes between water jet cutting companies may vary drastically among one another. Specifying cut quality is necessary to get an accurate quote and to ensure you are getting the quality/finish you need for your applications. Water jet cutting machines can cut a variety of materials of varying hardness, so materials should be considered as well.

There are five levels of edge quality. Some companies rank these Q1-Q5, where Q1 has the coarsest finish and Q5 has the finest. Other companies list these as Extra Coarse, Coarse, Medium, Fine, and Extra Fine. A slower cut will yield a finer finish. When cutting the hardest materials, an extra fine finish could take six times as long as an extra coarse finish on the same material. This is why pricing can vary so much, and why evaluating your specifications according to your budget is so important.

Some companies utilize water jet cutters with multiple heads that can make several cuts at one time, which can save you a lot of money while still getting a fine finish. Doing your research and being aware of all of your options will ensure that you get the best deal and the quality that you are looking for.

Broaching

Broaching CNC Machining

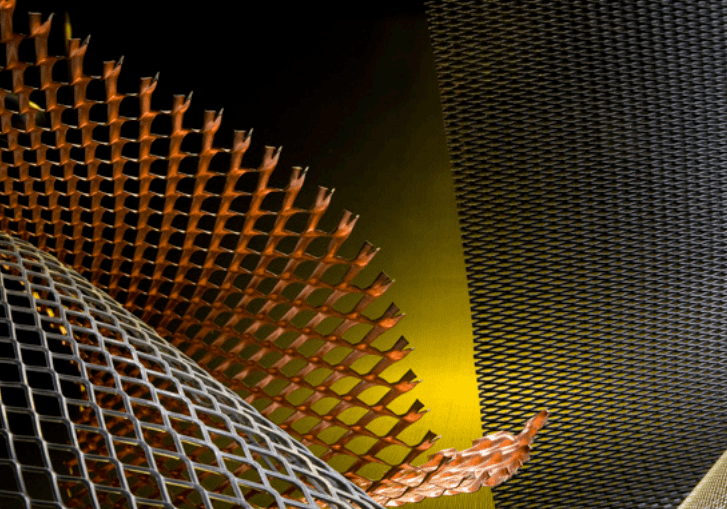

CNC Machining Expanded Metals

Expanded Metals Laser Cutting

Laser Cutting Metal Etching

Metal Etching Metal Fabrication

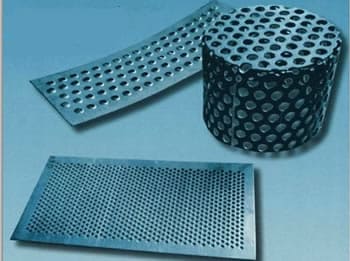

Metal Fabrication Perforated Metals

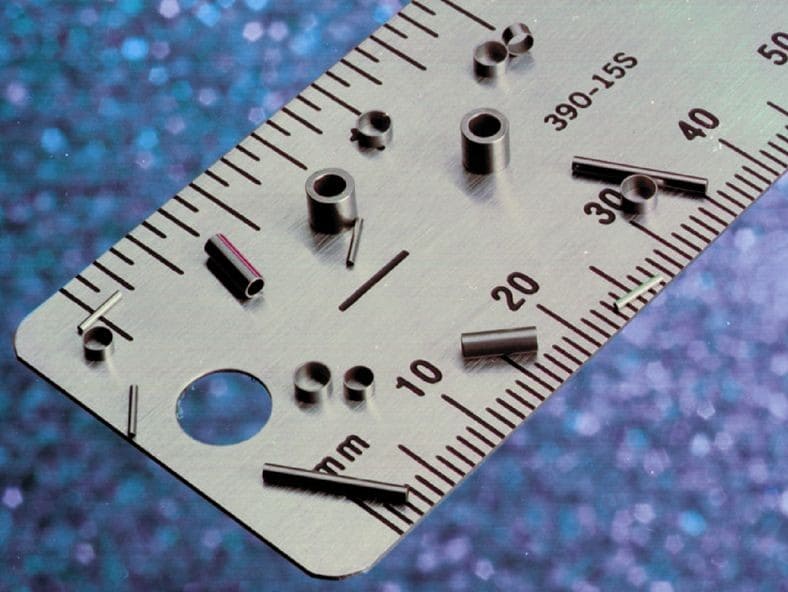

Perforated Metals Screw Machine Products

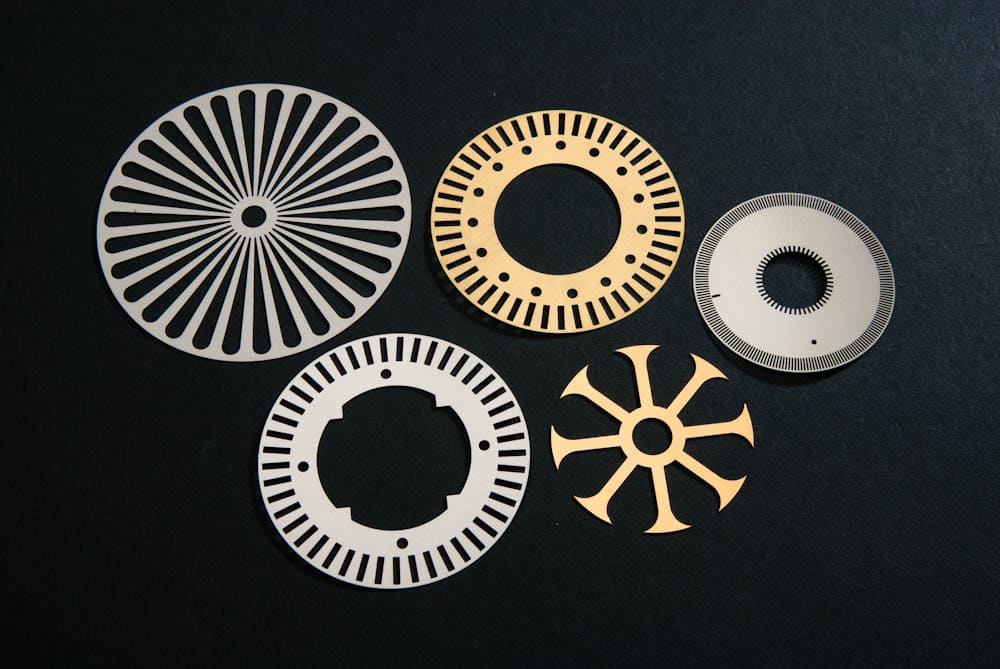

Screw Machine Products Metal Stampings

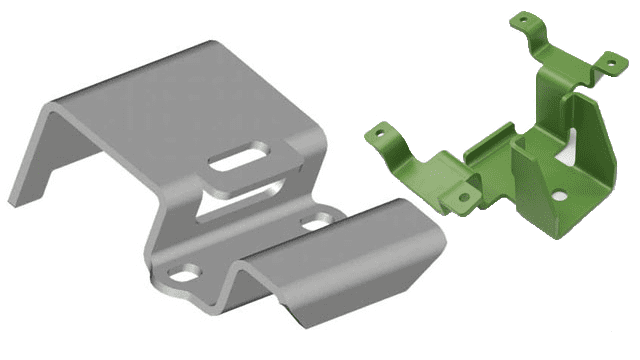

Metal Stampings Sheet Metal Fabrication

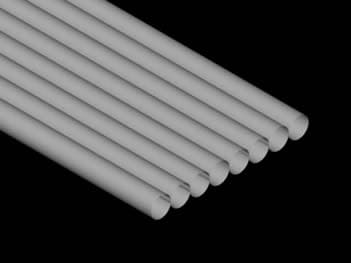

Sheet Metal Fabrication Tube Fabrication

Tube Fabrication Water Jet Cutting

Water Jet Cutting Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services